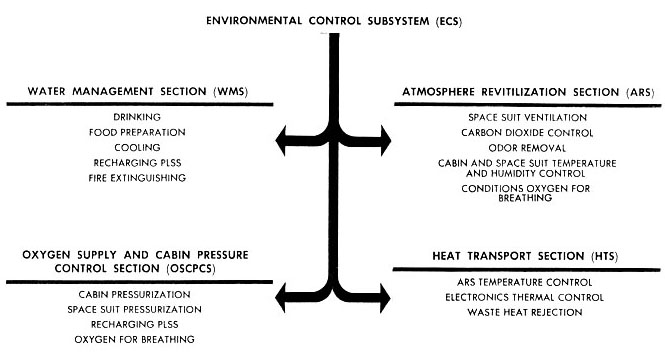

The major portion of the ECS is in the cabin. The peripheral ECS equipment, such as oxygen and water tanks, is located outside the cabin, in the ascent and descent stages. The ECS consists of the following sections:

Atmosphere revitalization section (ARS)The ARS purifies and conditions the oxygen for the cabin and the space suits. Oxygen conditioning consists of removing carbon dioxide, odors, particulate matter, and excess water vapor.Oxygen supply and cabin pressure control section (OSCPCS)

Water management section (WMS)

Heat transport section (HTS)

The OSCPCS stores gaseous oxygen and maintains cabin and suit pressure by supplying oxygen to the ARS to compensate for crew metabolic consumption and cabin or suit leakage. An oxygen tank in the descent stage provides oxygen during descent and lunar stay. Two oxygen tanks in the ascent stage are used during ascent and rendezvous.

The WMS supplies water for drinking, cooling, fire extinguishing, and food preparation, and for refilling the PLSS cooling water tank. It also provides for delivery of water from ARS water separators to HTS sublimators and from water tanks to ARS and HTS sublimators.

The water tanks are pressurized before launch, to maintain the required pumping pressure in the tanks. The descent stage tank supplies most of the water required until staging occurs. After staging, water is supplied by the two ascent stage tanks. A self-sealing valve delivers water for drinking and food preparation.

The HTS consists of a primary coolant loop and a secondary coolant loop. The secondary loop serves as a backup loop; it functions if the primary loop fails. A water-glycol solution circulates through each loop. The primary loop provides temperature control for batteries, electronic equipment that requires active thermal control, and for the oxygen that circulates through the cabin and space suits. The batteries and electronic equipment are mounted on cold plates and rails through which coolant is routed to remove waste heat. The cold plates used for equipment that is required for mission abort contain two separate coolant passages: one for the primary loop and one for the secondary loop. The secondary coolant loop, which is used only if the primary loop is inoperative, serves only these cold plates.

In-flight waste heat rejection from both coolant loops is achieved by the primary and secondary sublimators, which are vented overboard. A coolant pump recirculation assembly contains all the HTS coolant pumps and associated check and relief valves. Coolant flow from the assembly is directed through parallel circuits to the cold plates for the electronic equipment and the oxygen-to-glycol heat exchangers in the ARS.